Inverter

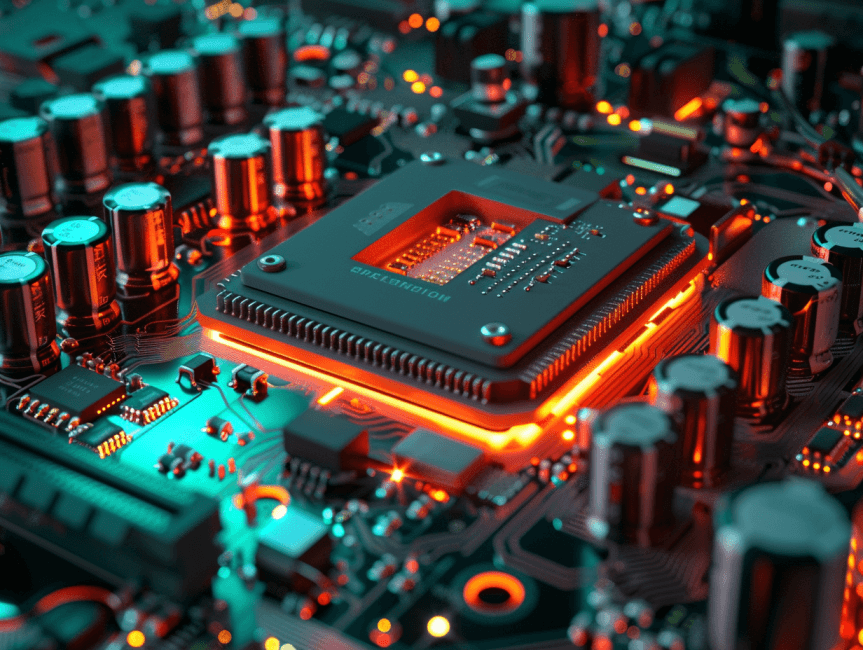

Our advanced Gallium Oxide based inverter elevates systems, setting new standards in efficiency and performance across critical applications. It achieves remarkable efficiency rates exceeding 99% and supports high-frequency operation up to 10MHz by harnessing the exceptional capabilities of Gallium Oxide (Gallium Oxide). Its outstanding thermal stability and high-voltage handling make it a versatile solution for various uses.

→ Efficiency Rate: Soars beyond 99%, significantly minimizing energy losses.

→ High-Frequency Operation: Enables operation up to 10MHz for compact, efficient designs.

→ High-Power Ga2O3-based Inverter Designs: Featuring 100 kW and 250 kW modules with advanced cooling strategies, Syrnatec's 650 V Ga2O3 MOSFETs offer unmatched power density by providing a current density 7x that of SiC and 3x of GaN.

→ Advanced Voltage and Device Capabilities: Supporting a 400V bus with 1200V versions in development, these devices offer high voltage handling and require sophisticated temperature management due to their lower thermal conductivity.

→ Innovative Cooling and Module Design: Ga2O3 modules use non-planar, orthogonal orientations with integrated liquid cooling to manage heat effectively and maintain module integrity.

→ Efficiency and Performance: Achieving efficiency rates beyond 99% and capable of high-frequency operation up to 10 MHz, these systems enhance efficiency and compactness in design.

→ Capacitor and Gate Driver Innovations: The design incorporates high-energy MLCC capacitors and a modified gate driver with advanced features for reliable, high-performance operation.

→ Thermal Stability and Power Output: Designed to operate reliably at up to 250°C and deliver up to 50 kW power output, the system combines thermal stability with high energy efficiency in a compact form.

→ Complementary Motor Design: Utilizing ceramic ferrite magnets for a rare-earth free design, the motor offers superior power density with a novel stator winding system to minimize capacitance and insulation stress.

→ Cost Efficiency and Production: Employing cost-effective materials and techniques, the motor design achieves an economical production cost of less than $3.3/kW for power levels up to 250kW.